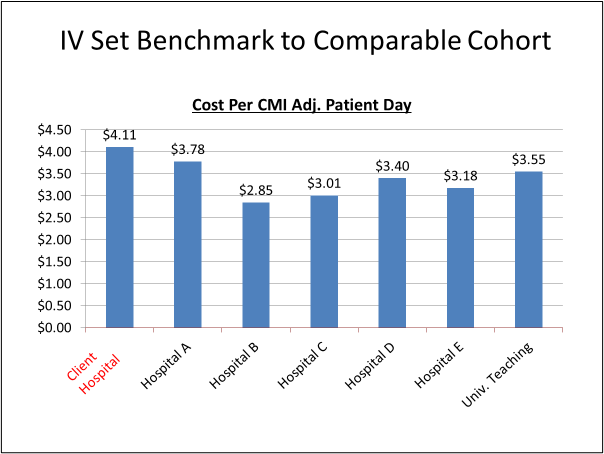

Clinical supply utilization benchmarking (sample shown in figure 1) is new to many supply chain professionals but is the fastest and surest way we have found to compare clinical supply utilization best practices between peer healthcare organizations. However, to be truly successful in clinical supply utilization benchmarking you must do these four things:

Figure 1

1. Identify your cohort or comparable group: We like to say that your ideal cohort group should be a mirror image of your healthcare organization with the same or similar operating characteristics, patient mix, and services. For instance, you wouldn’t compare a rural 26-bed critical access hospital to a university teaching hospital. Yet, there are exceptions where you can compare hospital departments with the same operating characteristics when your cohort group is ultra-specialized like dialysis clinics or pediatric departments.

2. Determine the current performance gap: In our example (figure 1) the current performance gap is $1.26 by comparing client hospital metrics to hospital B. Now, your hospital might not be able to reach this benchmark goal; however, it should be the starting point for setting a performance target. Based on this client’s adjusted patient days, this hospital has a potential of saving $96,784 annually on their I.V. sets, which also should be used as a savings target.

3. Measure, then observe current practice: Now that you know your IV set performance gap, you need to observe your hospital’s current practice. In this case, you need to observe (in-person) your IV team’s placement of IV sets.

4. Discover why you are different from your peer: Next, you need to interview a knowledgeable person at your peer benchmark hospital to determine their IV placement practice. Generally, this one step will give you the answer to this puzzle. In our client’s situation (figure 1), they were replacing their IV sets daily vs. per patient stay at their peer hospital. Once the difference was discovered and evaluated, our client changed their IV placement procedure to one per patient stay, thus saving over $100,000 annually by doing so.

Clinical supply utilization benchmarking has its champions, like SVAH, and detractors who we feel don’t understand how to benchmark or have used benchmarking services whose methodology or data have been flawed. It’s our belief that benchmarking is an art and science that can only be learned by performing thousands of benchmarking exercises. So, if you want to get better at benchmarking, practice, practice, practice, or look for a benchmarking service that has a minimum of 10,000 hours of experience in clinical supply utilization benchmarking.

P.S. If you would be interested in a FREE quote and demo of our Fast-Target Savings Assessment that will uncover 98% of your clinical supply utilization misalignments (like we have illustrated in figure 10) just e-mail me at [email protected].

Below are some similar articles that you may find interesting.

3 Ways to Ensure that Your New Product, Service, and Technology Supply Chain Savings Stick Each Year