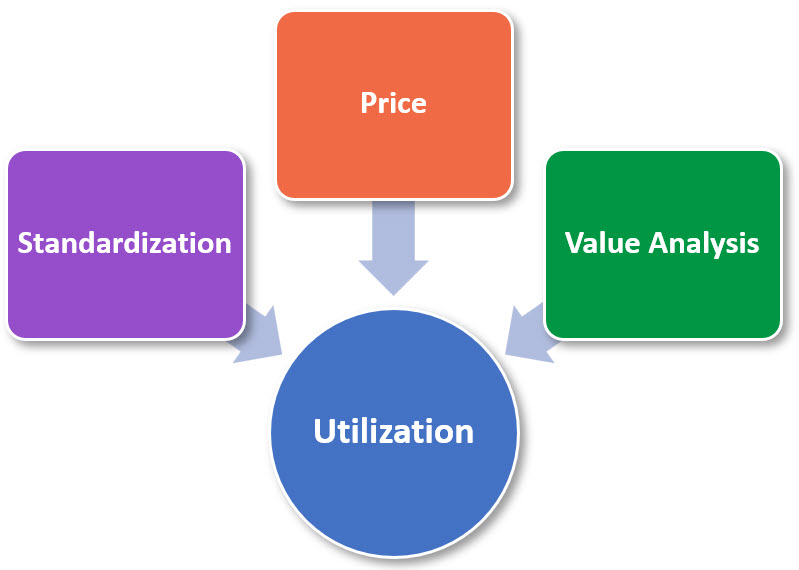

I can’t think of any healthcare organization that isn’t turning over every stone to find new supply chain expense savings opportunities. Yet, these same hospitals, systems, and IDNs often overlook a supply utilization strategy to wring the towel dry on their supply expenses. With this said, it has been our experience that there are only four ways to save on your supply chain expenses, as shown in our Supply Chain Expense Reduction Relational Strategies Model™ (Figure 1). With few exceptions, healthcare organizations’ price, standardization, and value analysis strategies are very mature and aren’t yielding double-digit savings as in prior years.

Figure 1: Supply Chain Expense Reduction Relational Strategies Model ™

A supply utilization strategy is so important since it can yield your healthcare organization an additional 7% to 15% savings on supplies and 11% to 18% on purchased services. This isn’t theory, but a fact that is backed up by hundreds of case studies, years of extensive research, and client testimonials.

Broaden Your Cost Management Objectives to Save More

Specifically, it is our estimate that you can still save 2% annually overall on your price savings, a few percentage points on standardization, and 3% to 5% on value analysis this calendar year. But if you broaden your cost management objectives to include supply utilization management, we estimate you could save an aggregate supply chain expense reduction of 12% on your healthcare organization’s supply expense budget within 12 to 18 months. This would be a major achievement for your hospital, system, or IDN, considering that inflation is raising its ugly head again.

There Is Nowhere Else to Go for Savings

We have observed how healthcare organizations save on their supply expenses for 37+ years and haven’t seen a cost reduction strategy that doesn’t fit into the categories of price, standardization, or value analysis tactics to save money. Unfortunately, these sources of savings are drying up because your vendors have no more price concessions to give, standardization has been substantially completed at most hospitals, systems, and IDNs, and value analysis isn’t employed as it was designed by Larry Miles, the father of value analysis. I call this a tipping point or the point at which a series of changes become significant enough to cause a larger, more important change. That change being a dramatic reduction in supply expense savings for healthcare organizations once they embrace a supply utilization strategy. In my opinion, there is nowhere else to go for supply expense savings.

Below are some similar articles that you may find interesting.

3 Tips About Value Analysis Software You Can’t Afford to Miss

4 Big Purchased Service Missteps That Your Contract Team Should Avoid