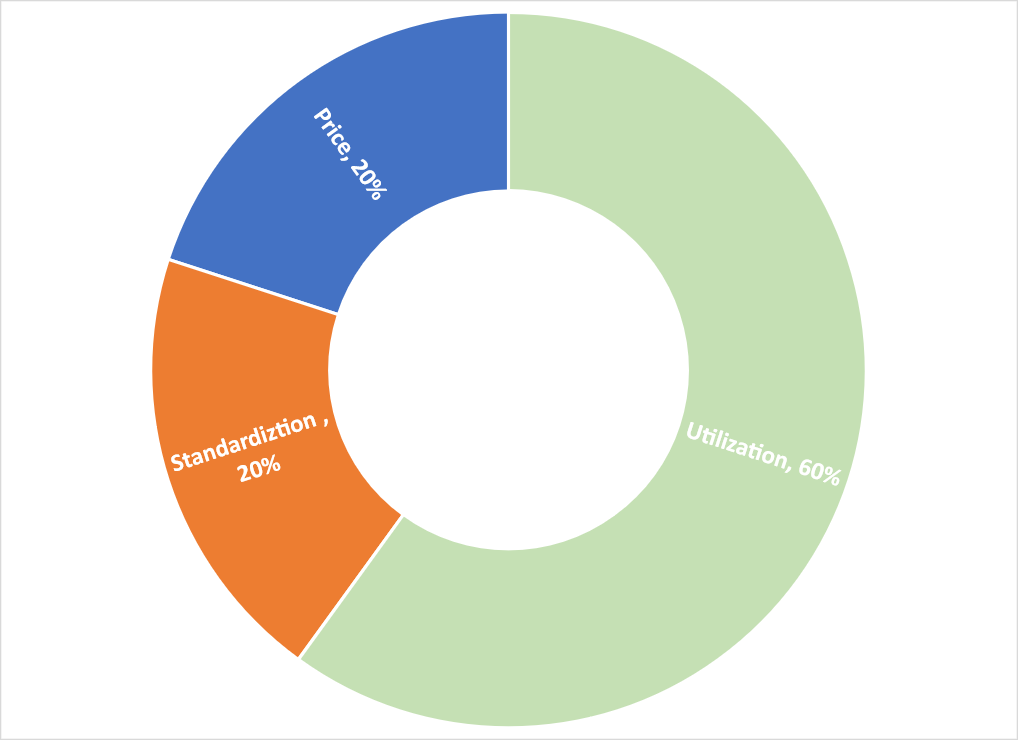

We are all looking to maximize the savings yields on our supply expense cost management initiatives, but too often we only focus on price as the predominant cost driver for all of our projects. We focus too much on price instead of striking the right supply expense balance, which includes attacking all of our supply expense cost drivers in alignment with their relative worth (e.g., 20% on price, 60% on utilization, and 20% on standardization). With this said, here’s how this “Supply Expense Balance Circle” (figure 1) concept works in the real world of supply chain management.

Figure 1: Supply Expense Balance Circle

Striking the Right Balance for Even More Savings

Price is an important factor in the “Supply Expense Balance Circle”, but once your commodity under investigation has been determined to be under a GPO or local contract, your price job is done. There is no reason to try to squeeze a few more pennies out of your contracts, since the savings won’t be significant enough to cover the internal cost of doing so.

It is much more prudent to concentrate 60% of your time investigating the utilization of the product, service, or technology because this is where your optimum savings reside. This requires establishing a baseline of activity-cost on each commodity under investigation so you can measure it to ensure that its running cost is within acceptable limits. For example, if your pulse oxisensor cost per adjusted patient day is $2.14 and your historical or baseline cost is $1.31 cents, or a 63% variance, you absolutely have a utilization misalignment that needs to be investigated. A typical 200-bed hospital with this profile could project utilization savings to be $101,000 annually. As you can see, this is much more savings than any price savings would yield for you.

Standardization of a product, service, or technology is a noble goal for supply chain professionals in most commodity groups, but over standardization can cost you money. This is because a one-size product, service, or technology doesn’t fit all of your customer requirements. For instance, we have seen hospitals standardize on a $5,600 general pacemaker, when in practice, a mix of pacemakers with the exact required functions, at an average price of $4,575, will meet your customers’ requirements exactly, thus saving $1,025 per pacemaker. So, why would you spend more than needed on your pacemaker’s functions than your customers require?

Optimizing Your Supply Chain Expense Savings Requires A Balanced Approach

From our observation, supply chain professionals are spending 80% of their time chasing price and standardization savings, while this results in less than 1.9% annual savings for their healthcare organization. This is while very little time is spent investigating their utilization misalignment (wasteful and inefficient consumption, misuse, misapplication, and value mismatches in supply streams) savings where the majority of their supply expense savings reside. A more balanced approached would be for supply chain professionals to spend 40% of their time on improving their price and standardization savings efforts and 60% of their time searching for and eliminating their utilization misalignments. This is what the “Supply Chain Expense Balance Circle” is all about: Concentrating your time on what matters, as opposed to looking for supply expense savings in all the wrong places.

Below are some similar articles that you may find interesting.

5 Questions To Answer When Formulating A Supply Utilization Management Strategy

Stop Losing Sleep Searching For Desperately Needed Supply Expense Savings

4 Key Elements of Savings Beyond Price to Address to Catapult Your Savings Yields In 2021