We identified supply utilization management as a new supply chain discipline about 18 years ago when the supply chain expense savings we were uncovering for our clients weren’t from price or standardization. After extensive research, we discovered that these new savings opportunities were caused by something else that we called utilization misalignments (defined as wasteful and inefficient consumption, misuse, misapplication, or life cycle shortfalls in supply streams). Since that time, we have observed hospitals’ supply utilization management maturity as they search for Savings Beyond Price™ as their price and standardization savings diminish. To help you increase your supply utilization management maturity, we have developed the Supply Utilization Management Maturity Model™ (Figure 1) as a guide to save you more in less time.

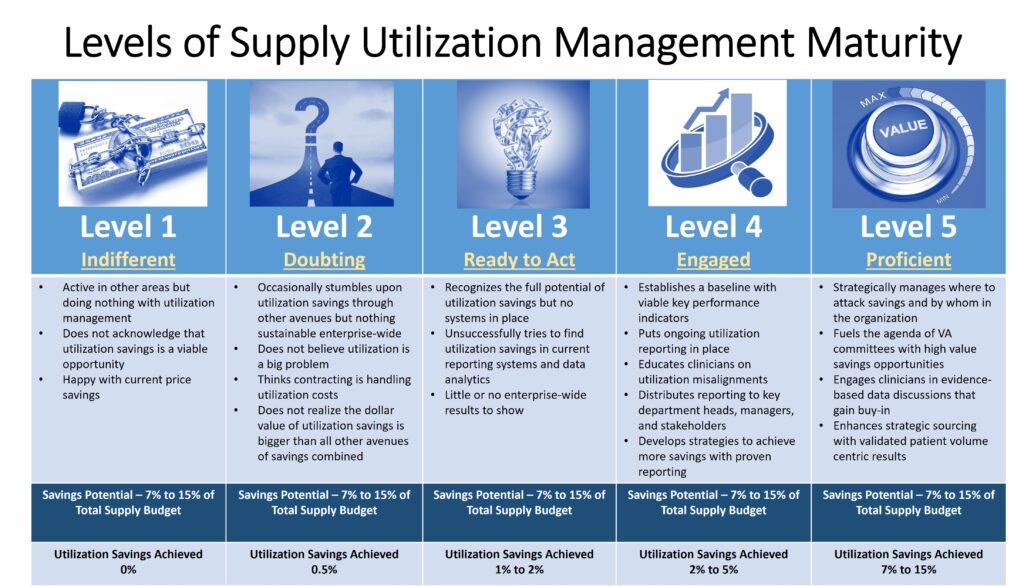

Figure 1: Supply Utilization Management Maturity Model

Below is a summation of the five levels of the Supply Utilization Management Maturity Model™. This model can change the way you look at your savings opportunities now and in the future.

Level 1: Indifferent (no savings) – Does not acknowledge that supply utilization is a viable savings source. Can’t believe savings could be in the range of 7% to 15% of their supply budget in a given year. Needs to educate themselves on the benefits of this new supply chain discipline to move to the next level.

Level 2: Doubting (.05% savings) – Occasionally stumbles upon supply utilization savings but isn’t focusing on this savings source. Thinks value analysis will manage this issue. Needs to realize that value analysis is still focusing on price and standardization – not supply utilization.

Level 3: Ready to Act (1% to 2% savings) – Recognizes the full potential of supply utilization management but has no enterprise-wide system in place to track, manage, and control it. Needs to investigate Clinical Supply Utilization Systems to manage data, analytics, and reporting of utilization misalignments.

Level 4: Engaged (2% to 5% savings) – Establishes a baseline with automated viable key performance supply utilization indicators. Develops strategies, tactics, and techniques to eliminate this unwanted cost. Distributes monthly supply utilization management reports to key department heads, managers, and stakeholders. Needs to stay focused on the big picture and not get bogged down in side issues.

Level 5: Proficient (7% to 15%) – Strategically targets supply utilization savings to avoid dry holes. Fuels value analysis agendas with new and better savings. Engages clinicians in evidence-based data discussions to gain buy-in. Needs to continue to refine reporting, education, and processes to yield even higher levels of savings and then make sure they stick through validation.

I believe that all supply chain professionals have heard the term supply utilization management, but have they embraced this new supply chain discipline at the highest level of proficiency? We believe that our Supply Utilization Maturity Model™ can be a good measurement tool for healthcare organizations who want to reach this goal.

Below are some similar articles that you may find interesting.

3 New Strategies to Uncover Additional Healthcare Supply Chain Savings

4 Things To Know About Hospital Supply Utilization Management To Increase Your Savings Yields